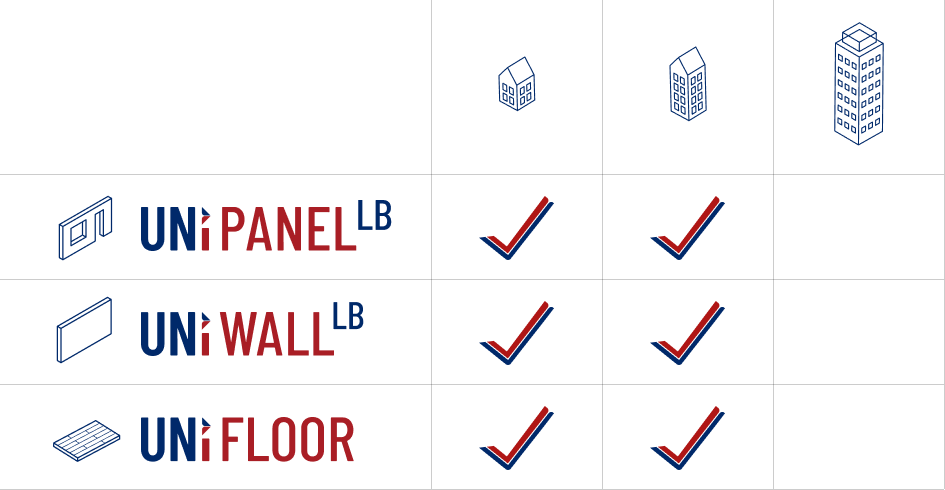

UNisystemLB (loadbearing) is designed for use in buildings of up to six storeys, with a maximum finished floor height of 18 metres. Every component of UNisystemLB will be familiar. The only difference is we're bringing these components together on our automated assembly line, to produce high-quality panels on repeat and to deliver dry building envelopes faster.

~2 days

It takes approximately two days to install the panels for a 2B3P semi-detached dwelling, if you're combining UNipanelLB and UNiwallLB with UNifloor. Other floor types e.g. composite floors will take slightly longer.

British Offsite can convert a traditional construction project to a hybrid manufacturing and construction project and deliver to site in as little as 120 days.

By eliminating the need for a support structure, UNisystemLB saves build time on site, making it a compelling choice for use on small apartment blocks, housing, commercial, health and education projects of up to six storeys. UNipanelLB is used for external walls and works in combination with UNiwallLB for internal compartmentalisation, and UNifloor, or another compatible floor system. Panels are supplied with sheathing boards and fitted with insulation and firestopping, for excellent thermal, acoustic and fire performance.

0.24 - 0.13 W/m2k

On

< 60 mins

On

< 120 mins

On

48dB minimum

(52dB nominal)

UNiwallLB is an internal compartmentalisation light gauge steel panel system, manufactured offsite incorporating internal insulation, sheathing boards, deflection head track, firestopping, MEP provision and entrance door openings with security mesh. Precision offsite manufacturing of UNiwallLB enables faster compartmentalisation of floors. Internal fitouts and customer viewings can take place sooner, helping developers to realise asset value earlier.

100mm - 200mm

Stud available circa May 2024

250mm - 8,400mm

Minimum / Maximum width

1,000mm - 3,200mm

Minimum / Maximum height

UNisystemSFS is designed for use in buildings of over six storeys and up to any finished height. The non-loadbearing components, UNipanelSFS (external walls) and UNiwallSFS (internal walls) operate as infill panels, working in conjunction with a loadbearing steel or reinforced concrete structure that delivers vertical load transmission and flooring. Once panels are lifted into place and secured, you have dry building envelopes. Internal fit out can begin on lower floors, while panels are still being lifted into place on floors above.

15 mins

Four UNipanels for a typical apartment can be installed on site in one hour. That's one panel complete with insulation, firestopping, windows and doors installed every 15 minutes.

That's why manufacturing your panels with British Offsite can improve first fork in the ground to first keys handover time by up to 30%.

UNipanelSFS is the external panel within our non-loadbearing UNisystem. It operates as an infill panel, working in conjunction with a loadbearing steel or reinforced concrete structure that delivers vertical load transmission and flooring. When a reinforced concrete frame is used, edge shuttering for the floor above is incorporated into the head of UNipanelSFS (as well as UNiwallSFS for internal compartmentalisation), eliminating any issues with tolerance to the underside of the concrete floor or beam. Deflection is accommodated via deflection joints built into the head of the panels.

0.29 - 0.12 W/m2k

On

< 60 mins

On

< 120 mins

On

48dB minimum

(52dB nominal)

UNiwallSFS panels for internal compartmentalisation of high-rise structures are manufactured using standard materials and assembly processes. However, just like UNipanelSFS, they can be adapted to specific structural, thermal, acoustic and fire requirements, calculated on a site-specific basis. UNiwallSFS is suitable for any high-rise building and in combination with UNipanelSFS produces rooms ready for internal fit-out, faster.

100mm or 200mm stud

Available

250mm - 8,400mm

Minimum / Maximum width

1,000mm - 3,200mm

Minimum / Maximum height

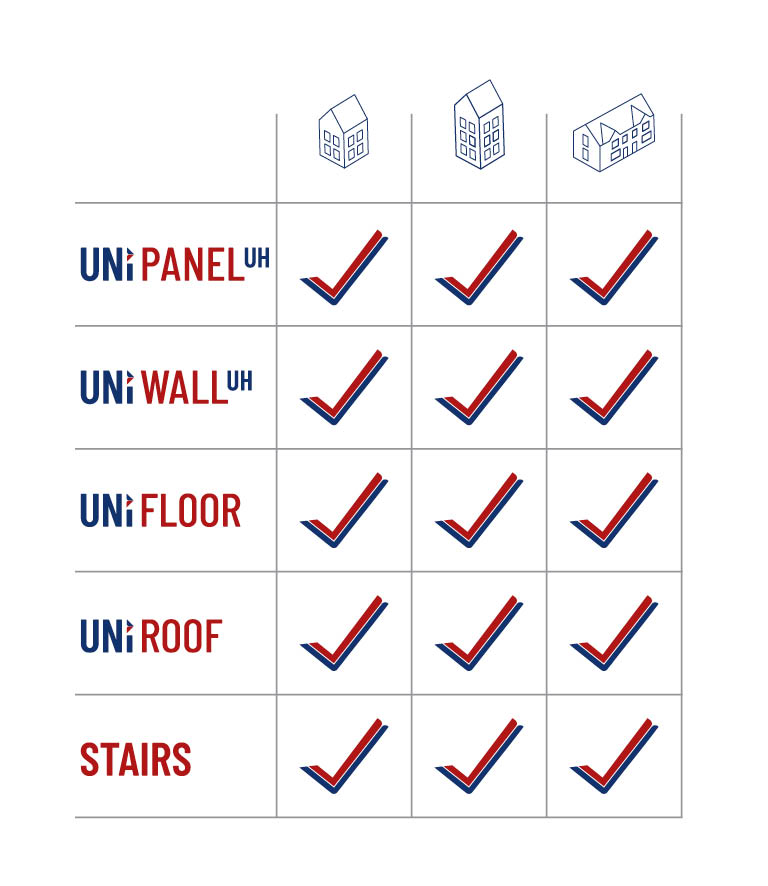

UNihouse has been developed specifically for rapid deployment in the low-rise housebuilding market. It utilises standard building materials to create a solution that has all the benefits of steel frame construction with none of the issues of timber frame or traditional brick/block building.

More built in

UNihouse is cost-competitive when compared like-for-like with wood frame panels. All pre-installed components should to be considered and their cost compared with the price of buying components separately plus the labour needed for onsite installation with wood frame.

UNipanelUH external walls eliminate the need for a support structure, saving build time on site and making UNihouse a compelling choice for housing of all kinds – detached, terraced or town houses – of up to three storeys in height. Our external panels can be used in combination with our internal compartmentalisation panels, UNiwallUH, as well as UNifloor or another compatible floor system.

Our internal walls, UNiwallUH (loadbearing), are a light guage steel compartmentalisation system. Panels are manufactured offsite incorporating internal insulation, sheathing boards, deflection head track, firestopping, MEP provision and entrance door openings with security mesh. Precision offsite manufacturing of UNiwallUH enables faster compartmentalisation of floors. Internal fitouts and customer viewings can take place sooner, helping developers to realise assets value earlier.

100mm - 200mm

Stud available

250mm - 8,400mm

Minimum / Maximum width

1,000mm - 3,200mm

Minimum / Maximum height

Project:

Discover how UNisystem was integrated into the superstructure of this mixed-use, residential-led development, in the busy London borough of Wood Green

Project:

Commercial and leisure spaces at Abbey Quay, Barking, were constructed using UNipanel, delivering essential community infrastructure faster, ready for residents to move in.

Project:

Enjoy the stunning design and architecture of this mixed used development in Hayes, where UNisysten enabled efficient delivery of three distinct blocks, with commercial space as well as apartment homes.

We are active members of several industry bodies and proud to achieve third-party accreditation for the performance of our products and systems.