.png)

British Offsite is a wholly owned subsidiary of The Weston Group, a builder of homes for over 35 years. With Group backing, we've created the next generation in light gauge steel frame construction and delivered one of the largest automated assembly lines in Europe.

The Group's confidence in UNisystem and invaluable insights from Weston Homes' design, technical and on site teams, enabled three years of product development before the launch of our Horizon factory in 2023. We continue to use products the construction industry is 100% familiar with but pre-manufacture more onto our panels, offsite. Enabling faster delivery of essential buildings and homes.

By hybrid, we mean integrating offsite methods of construction with traditional build – to remove manual processes from onsite and complete them faster and more efficiently offsite.

Manual processes will never be replaced completely but there are major productivity gains for developers who embrace a level of automation in their build programmes. We know from experience that work on site is more streamlined when you have precision pre-manufactured panels to work with.

We were developers before we became manufacturers, so we understanding the challenges for the construction industry – everything from skills shortages to demanding building regulation, supply chain pressures to environmental expectations. That’s on top of delivering a fantastic end product for customers and communities.

With our developer’s mindset we’ve created a 2D panelised system and invested in a state-of-the-art manufacturing facility, to meet these challenges head on. Our manufacturing solutions and services produce high-performance products that support your design vision and overcome common risks and delays in construction.

British Offsite is committed to advancing how the UK builds and helping every developer to adopt a hybrid approach to drive the performance of their business. It makes simple good sense to adopt hybrid. It’s safer, faster, more efficient, and delivers dramatic improvements in quality and environmental standards.

“I have great optimism for UK construction, that hybrid methods will become the norm and our sector will be more efficient and productive.”

Shaun Weston, Managing Director

Together with Randek AB, we’ve created one of the most automated light gauge steel panel assembly lines in Europe and the largest single production line in the UK to date. Automation and productivity solutions are complemented by skilled operatives. Working together they have quadrupled our production capacity to 10,000 lm – the equivalent of 6,000 homes per year.

Size180,000sq. ft

Capacity 6,000homes/year

Established 2023

Skyline was our first factory to manufacture UNisystem. Today it is dedicated to production of our BOS Fitout modules – kitchen, bathroom and wardrobe units for streamlined internal fitout of homes.

Size75,000sq. ft

Homes manufactured 3,000

Established 2017

Across our value chain – from product development to the final operation of buildings – we’re reducing energy consumption and waste and increasing the use of recycled materials. Our target is carbon net zero.

Steel is 100% recyclable without any loss of quality and today, on average, new steel products contain 37% recycled steel. We’re working with our international supply chain to increase this percentage and ensure our light gauge steel products are among the most sustainable in our industry.

We use durable packaging to protect our products while in transit, which is strong enough to reuse multiple times, reducing the overall volume of packaging we need. Our packaging is 100% recyclable so even when it’s no longer suitable for use, none of it needs to go to landfill.

Our precision, just-in-time manufacturing methods, utilising state-of-the-art machinery, enable us to optimise the use of raw materials, reducing the amount that goes to waste and the overall volumes we need. We’re committed to reusing or recycling our waste as far as possible to minimise the amount we send to landfill.

Energy efficiency is a key consideration as we continue to invest and grow, to make sure we’re playing our part in limiting global warming. Both British Offsite factories have solar panels on the roof. We continuously collaborate with our supply partners to reduce our energy footprint at all stages of production and to develop more energy efficient manufacturing equipment.

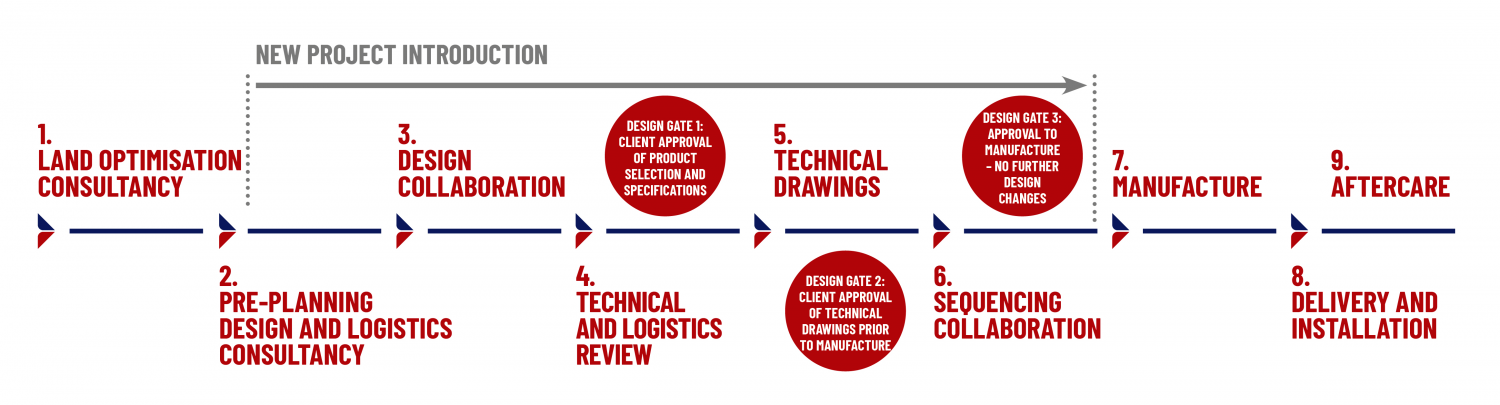

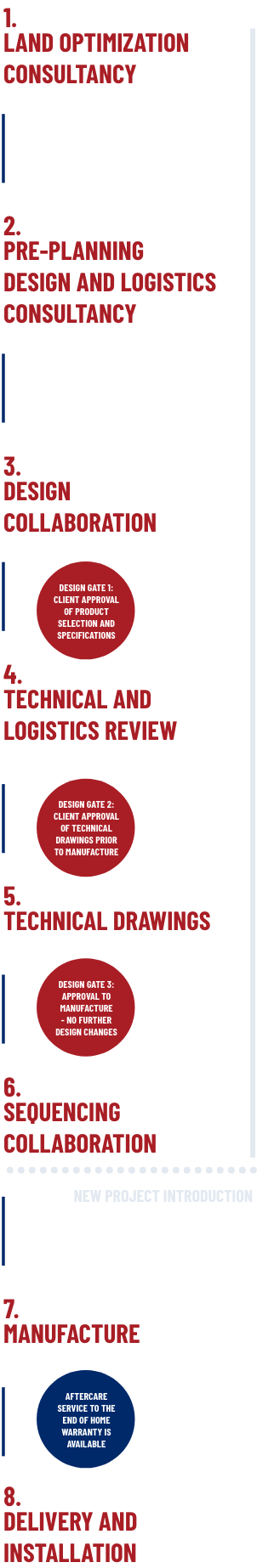

We partner with customers at every stage of the offsite process. As early as pre-planning to optimise applications with the inclusion of offsite strategies, right through to installation and aftercare.

Close collaboration on sequencing is essential before manufacturing begins and vital as site installation takes place, whether with British Offsite or your frame contractors. We're here to guide and support you all the way through.

Combining cutting-edge expertise in new builds, conversions and off-site construction, we partner with Weston Partnerships to deliver exceptional, sustainable housing at scale - empowering third-party developers and joint ventures to achieve outstanding results with speed and precision.

Our installer programme begins with a comprehensive two-day offsite training session, followed by an onsite assessment that concludes with the issuance of a competency card. This ensures your team is fully prepared to work with certainty and precision.

The programme kicks off at our state-of-the-art Horizon factory, where site teams are guided step-by-step through our detailed installation manual. Contractors will review the technical drawing pack and complete a knowledge check to reinforce critical concepts. The training also emphasises quality assurance and effective installation reporting.

As part of the hands-on experience, participants will practice installing a UNisystem panel at the Horizon factory. The programme culminates in a final onsite assessment during the initial deliveries, ensuring teams are equipped to operate safely and efficiently.

We are active members of several industry bodies and proud to achieve third-party accreditation for the performance of our products and systems.